Gravel-Lok® Technical Data

Read SDS and follow all safety instructions including use of proper eye, skin, and respiratory protection.

Click Here to download CADs and Data Sheets

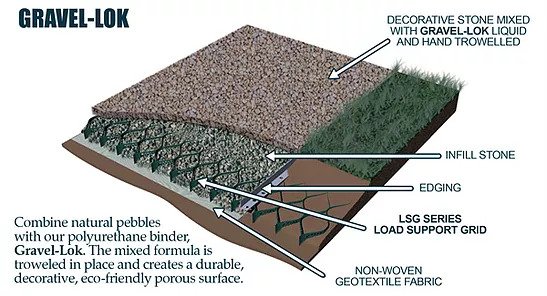

It is highly recommended you make test samples before starting any job to see the effect of the liquid on the stones. Properly grade subgrade to allow water to flow away from any structures. Add drainage if necessary. Install moisture barrier if project meets a foundation with a basement. Geotextile fabric must separate aggregates from subgrade and soils on all sides of the project.

- All aggregates must be very clean and free from any fine particles or dirt. The cleaner the stone, the stronger the bond.

- Store Gravel-Lok® at 68 degrees or above until ready to use.

- Do not install if rain is expected within 12 hours.

- Do not cover with plastic. This will trap in moisture and cause premature curing.

- Install when outdoor temperature is 50 degrees or above and will not drop below 50 for at least 12 hours. Allow 24 hours to cure.

- Rope off treated area to protect it from people and animals.

MIXING RATIO:

In most cases, mixing 20 oz. – 24 oz. of liquid in a clean, dry, 5 gallon bucket filled with stones is ideal.

Important: a plastic 5 gallon bucket is considered ‘full’ when the contents are filled 2” below the top of the bucket. Do not completely fill the bucket to the top with stones; fill to the “5 gallon mark”.

Our directions, included on every container, recommend a test to determine the correct mixing ratio because some stones absorb a little liquid during the mixing process:

Starting with a ratio of 20 oz. of liquid to 1 five gallon bucket of stone, mix the liquid with the stones and spread out at 1-1/2” thick on a piece of cardboard or wood. Allow to rest for 10 – 15 minutes. Remove gravel. If the liquid has dripped onto the cardboard or wood then the mixing ratio is correct. If you do not see any liquid on the cardboard or wood then repeat the process using 22 oz. of liquid. Again, if you do not see any liquid on the cardboard or wood then repeat the process using 24 oz. of liquid.

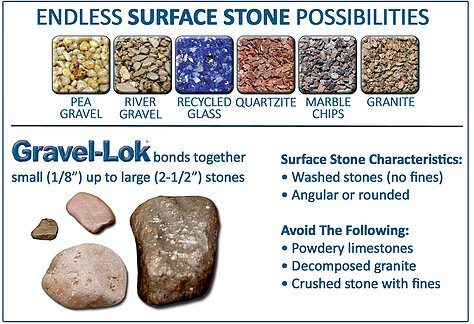

Note: if you are using stones which are very small (1/8”) then more liquid could be required. If you are using stones that are larger than ½”, then less liquid may be required. Gravel-Lok can only be used with stones between 1/8” and 2-1/2”.

Coverage Rates if test proves ratio of 20 oz. liquid : 5 gallon bucket of stones (based on using ¼”, 3/8”, and ½” size stone)

• At 1” thick: 186 sf / 5 gallon container of Gravel-Lok liquid when mixing and troweling at 1” thick ( or 37.2 sf / gallon)

• At 1.5” thick: 124 sf / 5 gallon container of Gravel-Lok liquid when mixing and troweling at 1.5” thick (or 24.8 sf / gallon)

• At 2.0” thick: 93 sf / 5 gallon container of Gravel-Lok liquid when mixing and troweling at 2” thick (or 18.6 sf / gallon)

If you perform the test described above and end up using the mix ratio of 24 oz. liquid : 5 gallon bucket of stones, then the coverage rates would be:

• At 1” thick: 144 sf / 5 gallon container of Gravel-Lok liquid when mixing and troweling at 1” thick (or 28.8 sf / gallon)

• At 1.5” thick: 96 sf / 5 gallon container of Gravel-Lok liquid when mixing and troweling at 1.5” thick (or 19.2 sf / gallon)

• At 2.0” thick: 72 sf / 5 gallon container of Gravel-Lok liquid when mixing and troweling at 2” thick (or 14.4 sf / gallon)

Finishing Roll Coat (highly recommended)

24 hours after initial installation use the same Gravel-Lok® liquid and a medium nap foam paint roller to apply a finishing roll coat. This important step replenishes any liquid that has dripped down through the system due to gravity during the curing process. In high traffic areas apply 2 – 3 roll coats. Each roll coat needs 24 hours to cure before applying the next.

Coverage rate: 400-500 sf per five gallon container (18-20 sf per gallon).

CLICK HERE TO DOWNLOAD COVERAGE RATES (PDF))

AGGREGATE OPTIONS:

A variety of materials may be used. The aggregates must be washed of dirt, fine particles, etc and needs to be dry before applying Gravel-Lok®. They should range in size from 1/8” to 2-1/2” and can be angular or round. Angular aggregates will lock together better. Round stones tend to be smoother on the feet.

MAINTENANCE:

Some loose stones may occur depending on the type of stone used and degree of abuse. A disturbed area can be treated with more Gravel-Lok® as needed.

Maintenance can include

- Patching any divots

- Applying roll coats

- In some cases, applying a ‘skim coat’ or ‘thin overlay’ of new stones mixed with Gravel-Lok® liquid.

STRENGTH:

The key to any pavement surface is the foundation it is built on. Cell-Tek’s geo-cellular confinement system constrains open graded aggregates which are used for porous surface applications and increases load support. The passive resistance of the infilled cells prevents lateral movement and distributes the load over a wider area.

DURABILITY:

Over time, a certain percentage of stones will come loose. Typically, about 1% of stones will come loose annually and this rate will increase with pedestrian or vehicular traffic. If the installation is located in a public space, the rate of loose stones will be even higher. The use of bikes, skateboards, roller blades, wheelchairs, luggage with wheels, shopping carts, etc. will increase the rate of loose stones. If there is patio furniture you may notice an increased number of stones coming loose where people pull in their chair and it drags across the surface of the pavement. Even high heeled shoes can cause additional stones to come loose. In the event of vehicular traffic (golf carts, forklifts, snow plows, lawn equipment, cars, etc.) a greater percentage of stones will come loose due to the pressure and traction of tires gripping the surface, especially where tires turn.

EDGING (RECOMMENDED):

Edging material may be wood, masonry, metal or plastic.

WINTER:

- Use caution with snow plowing equipment (gouging can occur)

- It is safe to use salt and other ice-melt products

- Expansion joints (saw cut) should be applied in climates experiencing frequent freeze-thaw cycles

POROSITY:

As with any permeable surface system, the system may become clogged over time. There are vacuum systems becoming increasingly popular which are designed specifically for porous surfaces. Recommended cleaning depends on site conditions and the amount of sediments the system is exposed to. Typical permeable systems become completely clogged within 5-7 years.

WET LOOK:

Gravel-Lok® may have a wet look appearance at first, especially the Clear formula. This will weather over time and restore the stone to more of a matte finish.